- Contact Person : Ms. wang Ida

- Company Name : Changzhou Zhongxiang Machinery Manufacturing Co., Ltd.

- Tel : 86-519-87391088

- Fax : 86-519-87397332

- Address : Jiangsu,LiYang,N.10 East Nanhuan Rd,shanghuang,Liyang,Changzhou,Jiangsu,China

- Country/Region : China

- Zip : 213314

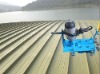

high quality door structure roll forning machine

:

Technical process | Decoiler→shovel head, pressure head→guiding, leveling→cut the head and tail of panel, welding connection→cold bend→hydraumatic cutting→discharging |

| Technical parameters | Raw material:Q195, Q235 galvanized plate or hot roll plate Raw material thickness:5mm Raw material width:about.750mm Motor power of decoiler :5.5KW Motor power of electric clip to send and of leveling device: 11KW Cold bending molding speed: 6-12m/min(not incl. Finished cut off, speed can adjust) Forming roll: level roller 20 to 24+ side vertical roll Roll materials : GCr15 Roll quenching hardness :HRC58-62° Main motive power: continuous current dynamo, matching reducer box Main motor power: 132kw Dynamo form: Continuous current dynamo reduction box: ZQ1000 Kind of drive: wheel gear distributor box, cardan shaft Drive gear box: outsourcing Cardan drive shaft: outsourcing Diameter of leveling the roller:140mm Material of leveling the roller :40Cr Independent arches frame: ZG230-450 or steel structure, annealing treatment. Bearing: cylinder roller bearing Cut mode; hydraulic cutting Hydraulic Power of shearing :15kw Error of length scale :10m/±5mm The material of shears: import SKD1 Hardness of Shear :HRC62° Electronic control system: PLC overall electric control+ division electric control The overall length of production line: 45-55m |

high quality door structure roll forning machine